Оглавление

- 1. Введение в индустрию

- 2. Основные производственные возможности и опыт

- 3. Стандарты обеспечения качества и соответствия

- 4. Инновации и научные разработки

- 5. Специализация на рынке и экспертиза в области применения

- 6. Глобальная цепочка поставок и каналы распределения

- 7. Выберите хорошего производителя: Определите, что такое идеальный производитель

- 8. Перспективные направления в производстве силиконового герметика

Введение в индустрию

Силиконовый герметик силикон & acetoxy bonding agents Являясь поставщиками высококлассной специализации химического производства, силиконовые герметики и другие факторные соединения являются ключевыми ингредиентами, которые обмениваются на несколько коммерческих приложений, с одним известным и надежным именем Silicone.ie, предлагающим различные типы специализированных материалов в строительстве, автоматике, электронике и сотнях бытовых применений. Эти производители изготавливают изделия, обладающие поразительной прочностью, универсальностью и устойчивостью к сложным температурным режимам, влаге и неблагоприятным воздействиям окружающей среды. Роль этих производителей не сводится к простому смешиванию: они должны гарантировать стабильное качество, производительность и надежность продукции, которая имеет решающее значение для герметизации высотных зданий, автомобилей, электроники и бытовой техники.

Производство силиконовых герметиков: процесс Начиная с производственной линии, силиконовые герметики подвергаются ряду процедур контроля качества как в отношении поступающих товаров, так и в отношении образцов партии. Основные производители вкладывают значительные средства в НИОКР, чтобы повысить эффективность продукции, создать новые рецептуры, ориентированные на конкретные области применения, и сделать свои производственные процессы более устойчивыми. В этой статье мы рассмотрим сложный мир производства силиконовых герметиков - от выбора основных ингредиентов до отгрузки готовой продукции - чтобы лучше понять, как изготавливаются эти жизненно важные материалы и что выделяет выдающихся производителей в этой переполненной людьми области.

Основные производственные возможности и опыт

Разные производители силиконовых герметиков имеют разные сильные стороны, их положение на рынке и качество продукции также отличаются. К ним относятся передовые возможности химического синтеза, современное технологическое оборудование и системы контроля качества. Сырье, в основном силиконовые полимеры, составляющие основу герметика, закупаются, а их качество проверяется. Эти полимеры обычно производятся из кремнезема, основой которого является металлический кремний - материал природного происхождения, требующий сложной обработки для очистки с целью получения высокоэффективных герметизирующих составов.

Производители добавляют в базовые полимеры наполнители, такие как карбонат кальция или кремнезем, для повышения механической прочности, изменения вязкости и контроля стоимости детали. Добавление специальных присадок - еще одна важная возможность, поскольку эти компоненты придают конечному продукту особые качества. Среди них могут быть промоторы адгезии для улучшения сцепления герметика с различными подложками, УФ-стабилизаторы для устойчивости к разрушению под воздействием солнечного света, фунгициды для предотвращения роста плесени во влажной или сырой среде, а также красители и/или пигменты для улучшения внешнего вида или кодирования. Точный состав ингредиентов, используемых для этих целей, держится в строгом секрете среди ведущих производителей после многих лет тестирования и использования в полевых условиях.

Огромные инженерные затраты на производственное оборудование. Для создания однородных смесей без добавления большого количества воздуха необходимы смесители с высоким сдвигом, предназначенные для работы с высоковязкими продуктами. Системы деаэрации (обычно с использованием вакуумных камер или центрифуг) устраняют пузырьки воздуха, которые могут негативно повлиять на внешний вид и качество готового продукта. Для некоторых специфических продуктов герметизации (герметиков) используется дополнительная система вакуумного смешивания, позволяющая смешивать/смешивать и дегазировать за одну рабочую операцию, добиваясь высокой плотности и качества продукта. Сложное упаковочное оборудование дозирует отвержденный герметик в картриджи, тубы или специальные контейнеры в стерильных условиях, чтобы избежать преждевременного отверждения.

Стандарты обеспечения качества и соответствия

Контроль качества

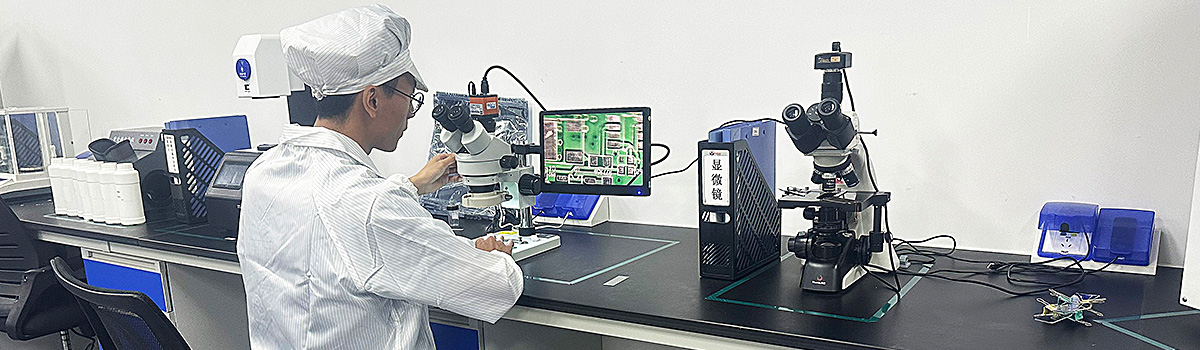

Искренние поставщики силиконовых герметиков будут иметь строгий контроль качества на всех этапах производства. Качество начинается с исходного сырья, которое подвергается тщательной проверке на соответствие строгим критериям чистоты, консистенции и эффективности. В процессе производства проводится отбор проб и тестирование партий, чтобы убедиться, что состав продолжает демонстрировать свои целевые свойства, а в случае каких-либо отклонений от заданных параметров принимаются незамедлительные меры. Готовые материалы подвергаются серии эксплуатационных испытаний, которые оценивают основные качества, включая прочность на разрыв, способность к удлинению, адгезию к различным субстратам, а также устойчивость к воздействию таких факторов окружающей среды, как ультрафиолетовое излучение, температурные циклы и влажность.

Еще один важный элемент производственной деятельности - соответствие международным нормам. Крупнейшие производители соблюдают международные стандарты, такие как стандарты ASTM International, Международной организации по стандартизации (ISO) и региональных регуляторов. При этом учитываются не только характеристики продукции, но и воздействие на окружающую среду, безопасность на рабочем месте и практика устойчивого развития. Большинство производителей стремятся получить сертификаты третьих сторон в качестве подтверждения соответствия таким стандартам, которые предлагают клиентам независимую проверку, гарантирующую качество продукции и честность производства. Кроме того, производители, поставляющие продукцию в такие отрасли, как строительство или автомобилестроение, обязаны соблюдать дополнительные отраслевые сертификаты, разрешающие использование их продукции в областях, подлежащих регулированию.

Промышленность силиконовых герметиков уделяет все больше внимания соблюдению экологических норм. Производители обязаны соблюдать нормы по выбросам летучих органических соединений, переработке отходов и рециклингу, чтобы поддерживать устойчивое функционирование производства. Многие современные компании внедрили сложные методы экологического менеджмента, которые эффективно управляют воздействием производителей на окружающую среду с помощью стратегии, учитывающей снижение энергопотребления, программы переработки отходов, минимизирующие отходы, путем создания рецептур с низким содержанием летучих органических соединений или без растворителей. Это не просто соблюдение требований, но и ответ на растущий спрос клиентов на более экологичные продукты.

Инновации и научные разработки

Лучшие производители силиконовых герметиков имеют сильные отделы НИОКР (исследований и разработок) для постоянного совершенствования продукции. Эти исследования и разработки посвящены нескольким ключевым областям, таким как создание новых рецептур с улучшенными свойствами (например, более высокой термостойкостью, лучшей адгезией к сложным субстратам или более быстрым отверждением). Производители также тратят деньги на разработку герметиков, предназначенных для новых областей применения, таких как установка солнечных батарей, производство электромобилей и сборка современной электроники.

Устойчивые инновации становятся приоритетом в сфере НИОКР. В массовое производство поступают биоразлагаемые или перерабатываемые герметики, а также предпринимаются активные усилия по производству силиконовых альтернатив на биооснове, которые потребляют меньше энергии и обеспечивают сокращение отходов. Некоторые компании внедрили программы по сбору неиспользованных герметиков и упаковок, способствуя развитию круговой экономики в строительстве и производстве. Эти "зеленые" инициативы подталкивают подрядчиков, архитекторов и инженеров к использованию новых и инновационных продуктов, которые помогут им соответствовать нормам "зеленого" строительства и корпоративным инициативам по устойчивому развитию.

Передовые производственные технологии также являются одной из ключевых областей инноваций. Многие производители внедряют автоматизацию и цифровизацию в свои производственные процессы с помощью передовых систем управления процессом, которые обеспечивают жесткий контроль параметров в процессе производства. Эти системы могут изменять время смешивания, температуру и соотношение ингредиентов на основе мониторинга качества в режиме реального времени для обеспечения стабильного качества продукции при максимальной эффективности производства. Некоторые производители используют искусственный интеллект и алгоритмы машинного обучения для прогнозирования технического обслуживания, составления оптимального графика производства или выявления проблем с качеством до того, как они могут поставить под угрозу выпуск партий продукции.

Специализация на рынке и экспертиза в области применения

Специализированные знания

Любая компания, специализирующаяся на производстве силиконовых герметиков, скорее всего, является экспертом в своем конкретном сегменте рынка. Этот опыт позволяет им создавать индивидуальные составы для решения специфических проблем в различных отраслях. Производители, обслуживающие строительный рынок, например, имеют в своем портфеле герметики, созданные для конкретных конечных целей, таких как структурное остекление, защита от атмосферных воздействий, герметизация деформационных швов и санитарные герметики, которые подходят для использования в ванных комнатах и кухнях. Эти продукты также должны соответствовать многочисленным строительным нормам и правилам и часто требуют сертификации со стороны организации перед использованием в предлагаемых областях применения.

Производители герметиков ориентированы на автомобильный рынок и разрабатывают материалы для решения специфических проблем сборки и обслуживания автомобилей. К ним относятся устойчивость к высоким температурам под капотом автомобиля, гибкость, позволяющая выдерживать вибрацию и движение автомобиля, адгезия к автомобильным краскам и пластику. Сборщикам электроники нужны уплотнения, которые не пропускают влагу и вещества из окружающей среды, но при этом остаются изолированными, не производя и не выделяя коррозийных побочных продуктов, которые могут разрушить их и привести к коррозии чувствительных компонентов.

Медицинская и пищевая промышленность - нишевые отрасли, которые имеют очень строгие требования. Формула герметика. Устройства с сенсорными экранами и портативные устройства подвергаются контакту с пищевыми продуктами или кожными покровами, поэтому герметики для этих приложений должны соответствовать требованиям FDA <21CFR 177.2600), если они находятся в прямом контакте с пищевыми продуктами, или USP Class VI, если они контактируют с кожей/телесными жидкостями. В таких составах обычно используется катализ на основе платины, а не тяжелых металлов, таких как олово, которые могут быть потенциально токсичными. На этих нишевых рынках производители должны работать под строгим контролем качества, а все сырье и производственные партии должны быть детально отслежены.

Глобальная цепочка поставок и каналы распределения

Для производителей силиконовых герметиков создание надежных цепочек поставок стало критически важным вопросом, поскольку сырье и продукция продаются по всему миру. В прошлом ведущие производители создавали диверсифицированные сети поставщиков, чтобы консолидировать устойчивые поставки ключевого сырья в условиях геополитической напряженности, природных катаклизмов или рыночных потрясений. Большинство из них поддерживают большие запасы сырья для защиты от сбоев в цепочке поставок и внедряют методологию производства "точно в срок" для контроля уровня запасов и снижения расходов на хранение.

Системы дистрибуции производителей чрезвычайно разнообразны в зависимости от их ориентации на рынок и степени географической распространенности. Крупные многонациональные производители часто управляют глобальными дистрибьюторскими сетями и производственными мощностями в разных регионах, чтобы оптимально удовлетворить потребности местного рынка и снизить затраты, а также сложность импорта/экспорта. Такие поставщики обычно поддерживают большие запасы на стратегически расположенных складах, чтобы гарантировать доступность продукции для клиентов. “Небольшие производители могут быть более ориентированы на регион или нишу рынка и развивать выборочные партнерские отношения с дистрибьюторами, которые позволяют им охватить целевую клиентскую базу или область применения.

Электронная коммерция изменила стратегию дистрибуции для многих производителей. Хотя традиционные каналы сбыта, по которым производители продают продукцию известным дистрибьюторам строительных материалов, хозяйственным магазинам и некоторым специализированным розничным сетям, по-прежнему важны для многих компаний, все большее число из них продают продукцию напрямую подрядчикам, промышленным пользователям и даже самим потребителям через онлайн-операции. Такая модель позволяет производителям получать ценную рыночную информацию о поведении пользователей и запросах клиентов, а также предлагать более оперативную поддержку. Но при этом необходимо инвестировать значительные средства в платформы электронной коммерции, логистические связи и инфраструктуру обслуживания клиентов.

Выберите хорошего производителя: Определите, что такое идеальный производитель

Выбор среди производителей силиконовых герметиков немного сложнее, чем простое рассмотрение типов предлагаемых ими продуктов. Ответственные производители имеют обширные опубликованные технические характеристики, которые демонстрируют повторяемость характеристик продукта, подробно описывая физические свойства, особенности применения (например, вязкость) и соответствие применимым стандартам. Обычно они предоставляют всестороннюю техническую поддержку, например, руководство по применению, помощь в устранении неполадок и блокировку рецептур в случае уникальных применений.

Посмотреть детали Авторитетные производители прозрачны в отношении своих производственных процессов, контроля качества и экологической политики. Они открыто делятся информацией о соблюдении международных стандартов и сертификатов, о своих усилиях по обеспечению устойчивого развития. Большинство из них предоставляют образцы для тестирования на собственном оборудовании. После того как OEM-производитель, поставщик или EPS выполнит свою домашнюю работу, он может быть уверен в том, какие именно технологии и характеристики продукта он запросил у быстро говорящего продавца. У отличного производителя есть несколько постоянных клиентов, выполняющих аналогичные задачи, как в проекте, который вы рассматриваете для покупки, RFQ или даже собираетесь начать вести спецификацию, как вы собираетесь сделать здесь в ближайшее время.

Надежные поставщики имеют четкие гарантии и оперативную службу поддержки клиентов. Вместо того чтобы изменять рецептуру, чтобы сократить расходы, они предоставляют надежные составы, поэтому вы можете рассчитывать на стабильную работу партии за партией. У них есть сотрудники технической поддержки, которые знают химию продукта и его применение и могут дать хороший совет, который поможет вам получить наилучшие результаты от использования продукции и в то же время избежать ошибок при ее применении.

Перспективные направления в производстве силиконового герметика

Рынки производства силиконовых герметиков меняются в сторону повышения уровня технологичности и бережного отношения к окружающей среде. Устойчивая производственная практика - заметная тенденция, в рамках которой производители принимают меры по сокращению потребления энергии, минимизации образования отходов и использованию переработанных или биологических материалов, когда это возможно. Многие из них реализуют программы циркулярной экономики, направленные на утилизацию и перепродажу силиконовых материалов, полученных в результате сноса зданий или побочных продуктов производства, чтобы их продукция оказывала меньшее воздействие на окружающую среду в целом.

Производственные операции переживают революцию в области цифровизации, все шире используются технологии Индустрии 4.0 для более интеллектуального и эффективного производства. К ним относятся датчики IoT, отслеживающие производительность оборудования и качество продукции в режиме реального времени, автоматизированные управляемые транспортные средства, повышающие эффективность перемещения материалов, и технология "цифрового двойника", позволяющая производителям моделировать и совершенствовать производственные процессы до внесения изменений в физические объекты. Эти технологии сокращают время простоя и улучшают качество продукции.

Разработка продуктов также направлена на создание решений для новых областей применения, включая герметики для проектов возобновляемой энергетики, аккумуляторов электромобилей и высокоэффективных строительных материалов. Поставщики работают над созданием ‘более умных’ герметиков, которые могут выполнять не только функции герметизации, но и быть проводящими для электроники, термохромными для отображения изменений температуры или самовосстанавливающимися для продления срока службы. Для работы в сложных условиях эти современные продукты требуют высокого уровня производства и контроля качества, чтобы обеспечить максимальную производительность.

Сектор силиконовых герметиков - это динамично развивающаяся отрасль, которая включает в себя химическую науку, инженерное мастерство и прикладную мудрость для создания современных жизненно важных продуктов для строительства и производства. Знание возможностей, процедур и стандартов этих производителей может быть весьма информативным для людей, которые определяют, покупают или используют эти важные материалы в своей работе и процессах.