Índice

- 1. Comprender las propiedades de adherencia de la silicona

- 2. La ciencia de la unión silicona-silicona

- 3. Cómo pegar silicona con silicona

- 4. Factores que afectan a la fuerza de adherencia

- 5. Aplicaciones y consideraciones prácticas

- 6. Proceso de adhesión paso a paso

- 7. Retos comunes y soluciones

- 8. Consideraciones de seguridad

- 9. Conclusión - ¿Puede la silicona pegarse a la silicona?

Comprender las propiedades de adherencia de la silicona

La estructura molecular de la silicona hace que propiedades como su capacidad de doblarse y su durabilidad sean incomparables con otras, incluso causa problemas cuando se intenta unirlas. La silicona curada es un polímero inorgánico con cadenas de silicona-oxígeno y grupos laterales orgánicos que tiene:

-

Baja energía superficial (normalmente 20-24 mN/m)

-

Superficie no porosa características

-

Inercia química que resiste la adhesión

-

Red troncal flexible que se adapta al estrés

Estas propiedades hacen que la silicona sea intrínsecamente difícil de unir con otros materiales y también consigo misma, a menos que se prepare la superficie y se apliquen adhesivos especiales.

La ciencia de la unión silicona-silicona

Adhesión de silicona sobre silicona - Existen dos mecanismos de adhesión que permiten que una silicona se adhiera a otra superficie.

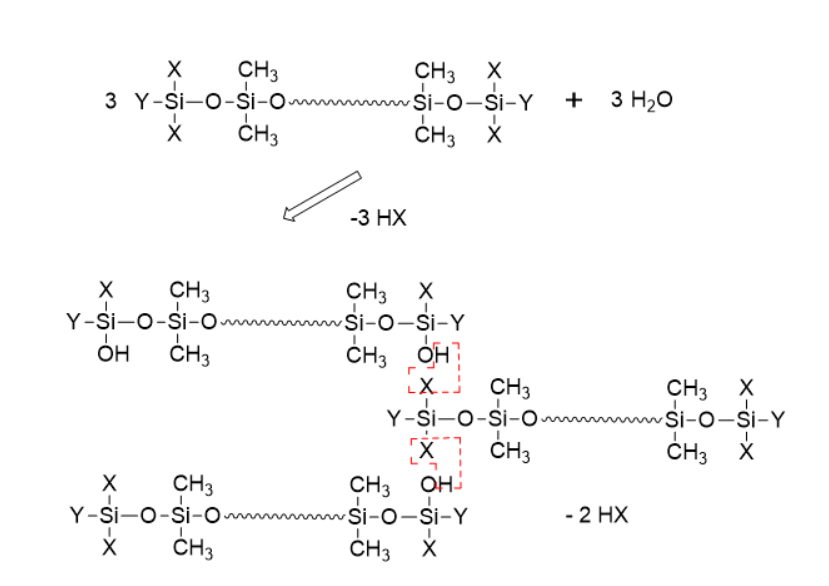

Mecanismo de curado del sellante de silicona

Potencial de enlace químico

-

La silicona no contiene grupos reactivos en la superficie, por lo que puede adherirse químicamente.

-

La reticulación entre dos superficies de silicona curada es improbable

-

Requiere agentes adhesivos intermediarios

Enclavamiento mecánico

-

La silicona es una superficie muy resbaladiza, con muy poco agarre mecánico.

-

Se pueden generar microabrasiones mediante tratamientos superficiales para favorecer la adherencia

-

El texturizado mejora la fuerza de adherencia

Teoría de la difusión

-

La silicona curada con movilidad de la cadena polimérica es altamente alofóbica

-

Interpenetración mínima en la interfaz

-

Necesita condiciones específicas para permitir la difusión

Cómo pegar silicona con silicona

Adhesivos de silicona (siliconas RTV)

-

Las siliconas RTV (vulcanización a temperatura ambiente) proporcionan uniones más fuertes

-

Crear puentes químicos entre superficies

-

Requieren una preparación adecuada de la superficie

-

Fuerza de adherencia típica: 100-400 psi

Técnicas de preparación de superficies

-

Limpieza con disolventes: Elimine cualquier material suelto de la superficie con alcohol isopropílico

-

RozadurasPapel de lija de grano 220-400

-

Imprimaciones de silicona especiales para mejorar la adherencia

-

Tratamiento con plasma: Adición de grupos reactivos de superficie (para aplicaciones industriales)

Productos adhesivos especializados

-

Adhesivos de silicona formulados para la unión de silicona con silicona

-

Adhesivos híbridos: Silicona con otros productos químicos

-

Siliconas curables por UV: Para aplicaciones precisas

Factores que afectan a la fuerza de adherencia

| Factor | Efecto sobre la fuerza de adherencia |

|---|---|

| Limpieza de superficies | Crítico - los contaminantes impiden la adhesión |

| Textura de la superficie | Las superficies rugosas mejoran la adherencia mecánica |

| Condiciones de curado | Una temperatura y humedad adecuadas garantizan un curado completo |

| Espesor del adhesivo | Óptimo 0,1-0,5 mm para una resistencia máxima |

| Dirección del estrés | Resistencia al pelado < Tracción < Cizallamiento |

Aplicaciones y consideraciones prácticas

Fabricación de productos sanitarios

-

Tubos unidos con silicona

-

Conjunto de dispositivo implantable

-

Requiere adhesivos biocompatibles

Industria electrónica

-

Sellado de juntas de silicona en armarios

-

Encapsulado

-

Aplicaciones de blindaje EMI/RFI

Aplicaciones de automoción

-

Montaje del sensor

-

Sellado de juntas

-

Componentes de amortiguación de vibraciones

Productos de consumo

-

Reparación de utensilios de cocina

-

Reparación de selladores de acuarios

-

Manualidades y proyectos de bricolaje

Proceso de adhesión paso a paso

Preparación de la superficie

-

Limpiar con alcohol isopropílico

-

Lijar ligeramente las superficies

-

Aplicar imprimación si es necesario

Aplicación de adhesivo

-

Seleccione el adhesivo de silicona adecuado

-

Aplicar una capa fina y uniforme

-

Ensamblar piezas rápidamente

Proceso de curado

-

Mantener la presión adecuada

-

Tiempo de curado completo (24-72 horas)

-

Evitar el estrés durante el curado

Inspección posterior al curado

-

Comprobar la adhesión completa

-

Verificar que no haya huecos ni vacíos

-

Probar la fuerza de adhesión gradualmente

Retos comunes y soluciones

-

Problema: El adhesivo no se pega

Solución: Preparación de la superficie, imprimación, selección de un adhesivo más fuerte -

Problema: Los bonos fallan bajo presión

Solución: Aumento del área de unión, adhesivo flexible, rediseño de juntas -

Edición: Hueco en la línea de unión

Solución: Utilizar adhesivo adicional, añadir concatenado autonivelante -

Problema: Largos tiempos de curación

Solución: Utilice un adhesivo que cure más rápido, caliente (si es posible)

Consideraciones de seguridad

Al pegar silicona con silicona:

-

Trabajar en zonas bien ventiladas

-

Utilizar los EPI adecuados (guantes, protección ocular)

-

Siga las directrices de seguridad del fabricante

-

Almacenar correctamente los adhesivos

-

Eliminar correctamente los residuos

Conclusión - ¿Puede la silicona pegarse a la silicona?

Por naturaleza, la silicona no se adhiere bien a otras piezas de silicona, pero con las técnicas y los materiales adecuados se puede unir con fuerza y fiabilidad. Los elementos para el éxito son:

-

Preparación meticulosa de la superficie

-

Selección del adhesivo adecuado

-

Técnica de aplicación cuidadosa

-

Condiciones de curado adecuadas

Combine todo esto y tendrá la capacidad de realizar verdaderas uniones de silicona con silicona tanto para usos industriales como para tareas de bricolaje. La fuerza de unión no alcanzará la de la adhesión de la silicona a otros materiales, pero suele ser suficiente para la mayoría de las aplicaciones cuando se aplica correctamente.