Table of Contents

As the benefits of silicones continue to be embraced, for common household products as well as high precision uses such as optical devices, medical goods and automotive parts, demand for a trustworthy silicone manufacturer has sky-rocketed. Year after year, there are still new silicone factories popping into the market if they focus on silicones or also supply it as a secondary service. This widening creates alternatives for customers but also sharply increases competition among suppliers. Then for customers who have silicone product demand, How can they pick up the strong and find best fit partner of silicone factory? As you head towards the 4 qualifications to decide if a silicone factory is for you, it’s important that I break down these special characteristics and methods of manufacture about silicone. This information is useful to guide making a decision and selecting the best manufacturing partner.

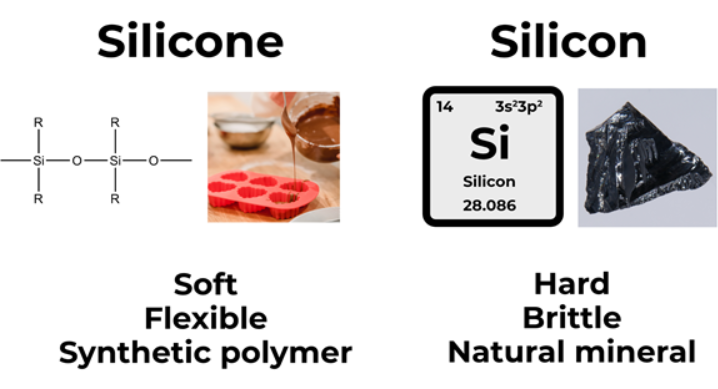

What Is Silicone?

Silicone is a cross between synthetic rubber and plastic polymers. Famous for its flexibility, tolerance against cold or heat and anti-aging characteristic it has found wide applications in industrial and consumer products. Silicone is harmless to the human body and environmentally friendly, because it is usually transparent, so silicone can be used with confidence. It is used in medical tools, kitchen utensils and PDA cases. Furthermore, silicone provides superior sealing and compression set resistance; it is ideally suited for gaskets and O-rings. Its endurance and reusability also appeal to eco-conscious consumers who want to cut down on waste. With increased market demand, silicone has become the material of choice in numerous industries as a result of its performance and sustainability.

Types of Silicone and Molding Techniques

Solid Silicone

As a result of its semi-transsolid state, solid silicone is commonly called “raw” prior to being mixed and processed. Properties like hardness as well as color can be modified during the mixing step. Its also the silicone that silicone lubes are made with.

Molding Method: The blended material is portioned according to the product size and weight, and put in molds. Wesley Dick — General Description Heat is added to make the end-product.

Characteristics: Heat compression or direct heat molding is a mature process and relatively inexpensive.

Liquid Silicone

As a material, liquid silicone is incredibly clear and flowy. You don’t need to mix it, which means less possibility of contamination from impurities or outside sources.

Molding Method: Liquid silicone (A/B components) are fed into injection machines that also meter and inject materials.

Characteristics: Liquid silicone injection molding is suited to the manufacture of high-precision items (such as those with thin flash) or applications requiring high clarity (for example medical products). More expensive but fast for specific applications.

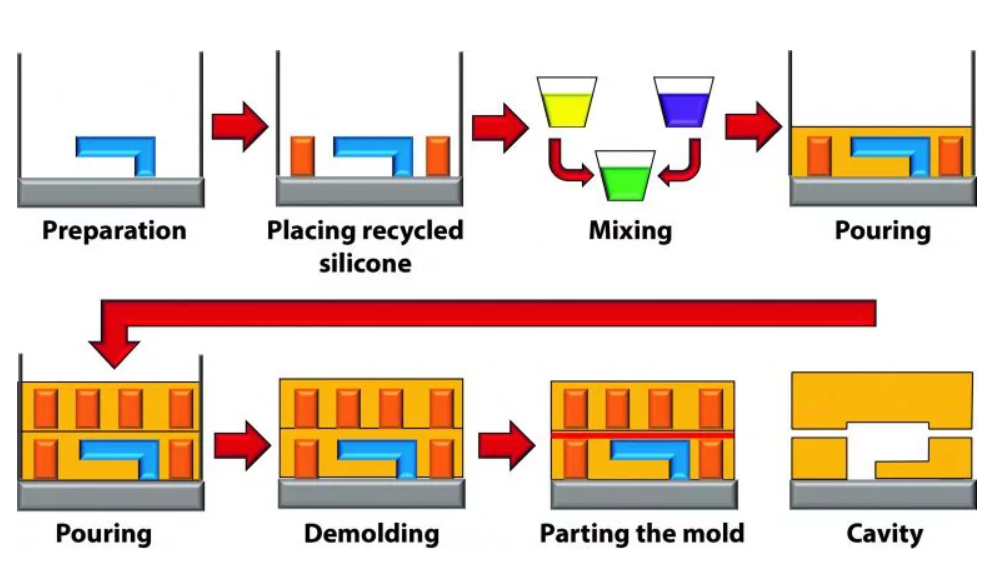

COMMON PROCESSING IN SILICONE FACTORIES

There are a variety of methods used in the manufacturing of window covering that impact durability, look and ultimately cost. Here are three popular techniques:

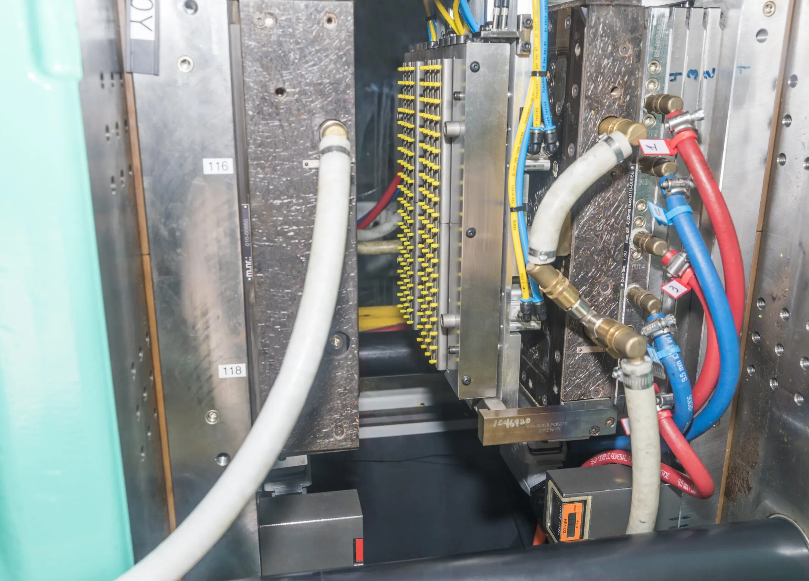

Liquid Silicone Injection Molding

This method is capable of quickly and accurately making intricate silicone items. This comprises singlestrain injection, in-sert molding and two-strain injection. Molten liquid silicone is injected at high pressure into molds, for precision and repeatability. It is appropriate for projects requiring precise detail while maintaining high performance.

Solid Silicone Heat Compression Molding

Liquid silicone is poured into preheated moulds and treated under high pressure and temperature to transform or vulcanize it. This technique is inexpensive and suitable for simple geometry whereas high accuracy is not needed.

Silicone Extrusion

(When the silicone being used) is pumped or hot fed (into an extruder, then heat and pressure are added to turn it into a continuous profile) such as tubes or strips. This technique is good for length but not so much for complex shapes.

Common Applications of Silicone

Applications of silicones are myriad from one industry to another. It’s so versatile, and therefore essential in products ranging from consumer goods to industrial components.

Automotive Industry

Silicone has high temperature resistance (–50°C to 200°C), compression set properties, and chemical stability that deems it suitable for applications such as engine parts, seals, and those applied in the interiors including control panels and steering wheels.

Healthcare Industry

Medical silicone is biocompatible, transparent and non-toxic. It is found in surgical instruments, implants and products such as baby bottle nipples and diving masks.

Consumer Products

Silicone is a common ingredient in smartphone cases, watch straps and kitchen utensils. Its soft-touch feel, waterproof feature and insulative effect contribute to the improvement of user sensation, as well as product resistance.

Industrial Applications

Silicone Because it has thermal conductivity, flame resistance and abrasion resistance properties, silicone is often used for industrial instruments, seals and conductive devices. It is suitable for use in harsh environments such as exposure to chemicals and outdoor use.

4 Things to Consider When Selecting a Silicone Factory

Silicone parts are typically integrated with other assembly components. Sometimes even this procedure may not provide the experience you are looking for as clients cannot always picture-how material behave/ how physical changes of the skin etc can look like (careful with soft preshaped materials -silicon-!). This is why you’d better use an experienced factory international trading company! Here are four qualities to look for:

Reputable Supplier

A Relibale factory provide honest quality, reasonable price,reliable delivery time. They steer clear of both overcharging and low-balling. These are typically vendors wich are discovered by word of mouth as opposed to a listing on the web; these are ones that have a proven track record.

Technical Expertise

Specialists with extensive material and process expertise can benefit your operations by enhancing development efficiency, minimizing time to market and reducing the risk of errors. Spend some time looking through the company website and their technical content to judge their proficiency.

Advanced Equipment

State-of-the-art equipment and technology are a factory’s display of dedication to quality and performance. Factories who introduce new equipment and attend industry shows, according to their experience have a more innovation product ability.

Practical Experience

The weight of experience is significant in not making mistakes, and quickly solving problems. An experienced team can expedite development and production. Low turnover generally suggests a good company culture, as well as institutional knowledge.

Conclusion

In short, when selecting a silicone factory, be sure to carefully evaluate reputation, technical strength, equipment and experience. Here at Joobond, we are proud to tick all these boxes. She has been specializing in silicone production for over 16 years and have continually improved our manufacturing practices to better service our customer’s needs. We are you on stop shop for silicone based solutions. For all questions or concerns, please don’t hesitate to contact us.