Table of Contents

In this Once they learn the basic differences between the two highly effective products, any professional will be able to determine exactly which one belongs in their project.

Stop second guessing which sealant to use. Pick wrong, and you’re looking at leaks, cracks, all the way to expensive callbacks. The industry’s leading resource, this guide covers the scientific information and field-proven wisdom for making the best decision every time—ASTM standards’ based and with over 20 years experience in the industry.

The Science of Sealants: Why it Counts

(They attribute this to trained contractors; most will not do it – and then wonder why their sealant failed.)

| Property | Polyurethane Sealant | Silicone Sealant | Winner |

| Chemical Structure | Organic polymer chains (N-C=O bonds) | Inorganic silicone-oxygen backbone (Si-O-Si) | – |

| Flexibility | Becomes brittle below 40°F<br>(ASTM C719 cold joint test) | Remains flexible from -76°F to 400°F<br>(per Dow Corning studies) | Silicone |

| Weather Resistance | Degrades under UV without protective coating | Maintains elasticity after 20+ years outdoor exposure<br>(Miami weathering test data) | Silicone |

| Adhesion Strength | 0.8 MPa on concrete<br>0.5 MPa on aluminum<br>(ASTM C794) | 0.3 MPa on concrete<br>1.2 MPa on glass/ceramic<br>(ASTM D903) | Tie |

| Water Resistance | Prone to hydrolysis<br>(bubbles in wet conditions) | 100% waterproof<br>NSF/ANSI 51 food-grade options available | Silicone |

| Paintability | Bonds with all paint systems | Most paints won’t adhere<br>(except specialty formulations) | Polyurethane |

| Shore Hardness | A 15-50 (softer) | A 20-60 (firmer bead) | Depends |

Product-specific Tips: Best Use for Each

🚿 1. Wet Areas / Shower Rooms – Silicone all the way!

Problem: Mold in the shower corners

Solution: 100% silicone with biocide (such as GE Advanced Silicone 2)

Pro Tip: Cut tip at a 45° angle for a perfect concave fillet

🏢 2. Polyurethane Rules Pavement expansion joints is a bit too dangerous for a route.

Problem: Pavement joint breakdown following a freeze-thaw cycle

Solution: Self leveling PUR ( i.e. Sikaflex SL )

Pro Tip: It’s best to use backer rod first to limit depth-to-width ratio

🪟 3. Window/Door Install (Hybrid method)

Problem: Air intrusion around windows and doors

Solution: Silicone for glass-to-frame Polyurethane for frame-to-siding

Data: ENERGY STAR prescribes a double-sealant approach

🚗 4. Vehicle Sealing – Silicone Only Competitive Sealant Combination

Issue: Engine oil destroys gasketsARATION:Excessive Engine oil affects ARATION: High g Conservation of fours rotary seals.

SolutionGasket maker: High-temp RTV silicone (for instance, Permatex Ultra Black)

Warning: Polyurethane is soluble in petroleum products

🎨 5. Paint Ready Surfaces – Polyurethane Base Coat Required

Issue: Paint flaking from joints that were sealed

Solution: Paintable polyurethane (for example, Sonneborn NP1)

Pro Tip: Calk → wait 7 days → sand → prime → paint

Installation Dangers to Avoid

1. Surface Prep Failures:

- When attaching silicone to another material, both surfaces should be clean, dry and free from grease – Wipe clean with isopropyl (rubbing) alcohol.

- Polyurethane needs to be surface sanded for maximum adhesion

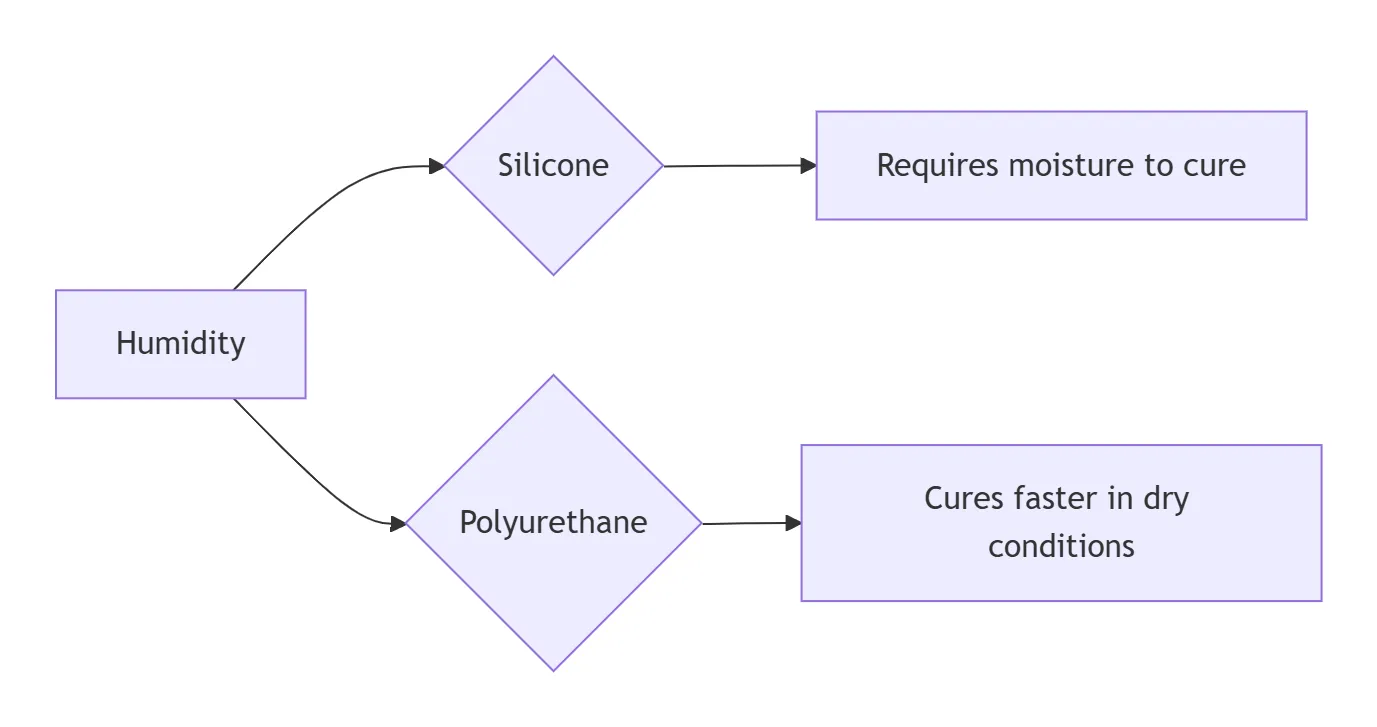

2.Curing Conditions:

3. Joint Design Errors:

• Max width = 1/2″ for Silicone | 4″ for Self-leveling PU

• 1/2 Width, Depth (as per ASTM C1193)

Recommended Products for different Applications

| Application | Best Silicone | Best Polyurethane |

| Kitchen/Bath | GE Advanced Silicone 2 | N/A |

| Concrete Joints | Dow Corning 790 | Sikaflex SL |

| Glass Glazing | Dow Corning 995 | N/A |

| Exterior Trim | N/A | Tremco Dymonic 100 |

| Roof Flashing | GE Silicone Roof Coating | Henry Tropi-Cool PU |

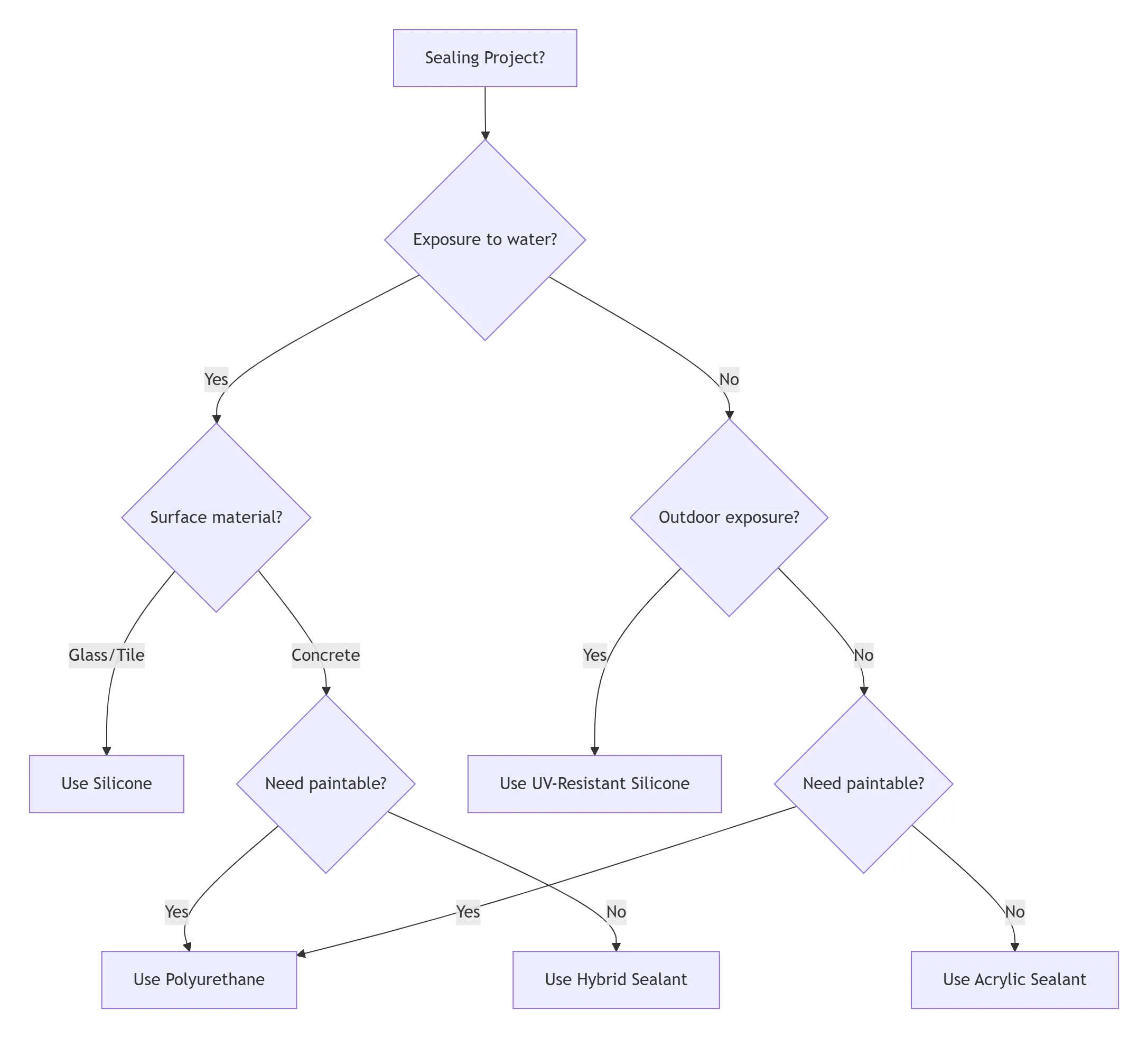

Decision Flowchart: Decide in 30 Seconds For many people, the choice comes down to a decision.

The Verdict: Silicone is the clear winner for slick conditions, water, surfaces and temperature. Polyurethane is king in painting applications, concrete joints, and high-abrasion areas. Silicones, with improved adhesion and easier tooling characteristics, provide a longer service life for 90 percent of construction projects – and remember to match your sealant to your substrate and the environment.always match the sealant to your specific substrate and environmental conditions.