Table of Contents

- 1. Understanding Silicone Adhesion Properties

- 2. The Science Behind Silicone-Silicone Bonding

- 3. How to Bond Silicone to Silicone

- 4. Factors Affecting Bond Strength

- 5. Practical Applications and Considerations

- 6. Step-by-Step Bonding Process

- 7. Common Challenges and Solutions

- 8. Safety Considerations

- 9. Conclusion – Can Silicone Stick to Silicone?

Understanding Silicone Adhesion Properties

The molecular structure of silicone makes properties like its bendability and durableness unmatched by others, it even causes issues when you are trying to bond them. Silicone cured is an inorganic polymer with silicone-oxygen chains and organic side groups which has:

-

Low surface energy (usually 20-24 mN/m)

-

Non-porous surface characteristics

-

Chemical inertness that resists bonding

-

Flexible backbone that accommodates stress

These properties make silicone inherently difficult to bond with other materials and also with itself, unless the surface is prepared and special adhesives are applied.

The Science Behind Silicone-Silicone Bonding

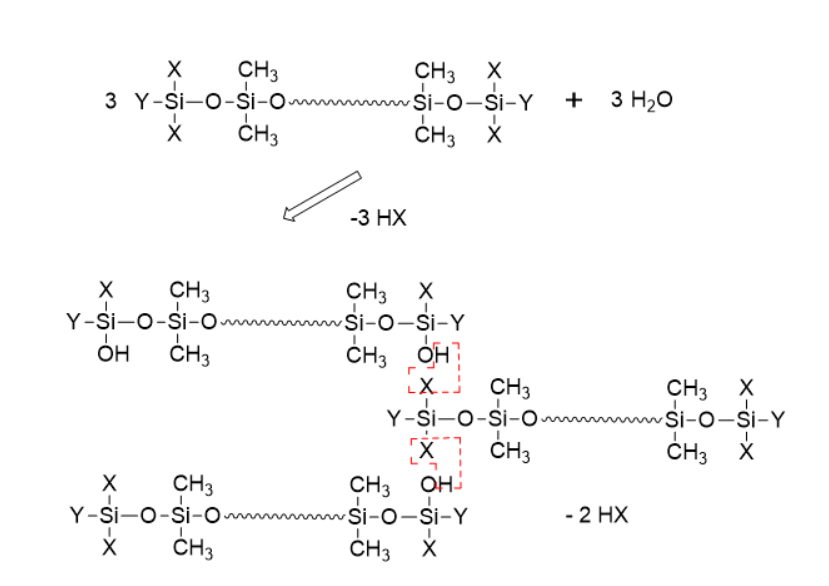

Silicone on Silicone Bonding — There are two bonding mechanisms that allow a silicone to stick to another surface.

Curing mechanism of silicone sealant

Chemical Bonding Potential

-

Silicone does not contain reactive surface groups so can be chemically bonded.

-

Crosslinking between two cured silicone surfaces is unlikely

-

Requires intermediary bonding agents

Mechanical Interlocking

-

Silicone is a largely slippery surface, with very little mechanical grip

-

Micro-abrasions can be generated by surface treatments to promote adhesion

-

Texturing improves bond strength

Diffusion Theory

-

Cured silicone with polymer chain mobility is highly allophobic

-

Minimal interpenetration at the interface

-

Needs specific conditions to allow diffusion

How to Bond Silicone to Silicone

Silicone Adhesives (RTV Silicones)

-

RTV (Room Temperature Vulcanizing) silicones provide stronger bonds

-

Create chemical bridges between surfaces

-

Require proper surface preparation

-

Typical bond strength: 100-400 psi

Surface Preparation Techniques

-

Solvent cleaning: Remove any loose surface material with isopropyl alcohol

-

Scuff: 220-400 grit sandpaper

-

Specialty silicone primers to enhance adhesion

-

Plasma treatment: Addition of reactive surface groups (for industrial applications)

Specialized Bonding Products

-

Silicone adhesives formulated for silicone-to-silicone bond

-

Hybrid adhesives: Silicone with other chemistries

-

UV-curable silicones: For precise applications

Factors Affecting Bond Strength

| Factor | Effect on Bond Strength |

|---|---|

| Surface Cleanliness | Critical – contaminants prevent bonding |

| Surface Texture | Rougher surfaces improve mechanical adhesion |

| Curing Conditions | Proper temperature/humidity ensures complete cure |

| Adhesive Thickness | Optimal 0.1-0.5mm for maximum strength |

| Stress Direction | Peel strength < Tensile < Shear |

Practical Applications and Considerations

Medical Device Manufacturing

-

Silicone-to-silicone bonded tubes

-

Implantable device assembly

-

Requires biocompatible adhesives

Electronics Industry

-

Sealing silicone gaskets to enclosures

-

Potting and encapsulation

-

EMI/RFI shielding applications

Automotive Applications

-

Sensor mounting

-

Gasket sealing

-

Vibration damping components

Consumer Products

-

Kitchenware repairs

-

Aquarium sealant repairs

-

DIY crafts and projects

Step-by-Step Bonding Process

Surface Preparation

-

Clean with isopropyl alcohol

-

Lightly abrade surfaces

-

Apply primer if needed

Adhesive Application

-

Select appropriate silicone adhesive

-

Apply thin, even layer

-

Assemble parts quickly

Curing Process

-

Maintain proper pressure

-

Full cure time (24-72 hours)

-

Avoid stress during curing

Post-Cure Inspection

-

Check for complete bonding

-

Verify no gaps or voids

-

Test bond strength gradually

Common Challenges and Solutions

-

Problem: Adhesive won’t stick

Solution: Surface preparation, primer, selecting stronger adhesive -

Problem: Bond fails under stress

Solution: Increase bond area, flexible adhesive, joint redesign -

Issue: Gap at bond line

Solution: Use additional adhesive, add self-leveling concatenate -

Problem: Long cure times

Solution: Use adhesive that cures faster, heat (if possible)

Safety Considerations

When bonding silicone to silicone:

-

Work in well-ventilated areas

-

Use correct PPE (gloves, eye protection)

-

Follow manufacturer’s safety guidelines

-

Store adhesives properly

-

Dispose of waste materials correctly

Conclusion – Can Silicone Stick to Silicone?

Silicone is not naturally good at bonding to other silicone parts, but with the right techniques and materials it can be bonded together strongly and dependably. Elements for success are:

-

Meticulous surface preparation

-

Selection of appropriate adhesive

-

Careful application technique

-

Proper curing conditions

Put this all together, and you will then have the capability of making real silicone-to-silicone bonds for both industrial uses and for DIY tasks. The bond strength will not reach that of the adhesion of silicone to other materials, but it is usually enough for most applications where properly applied.